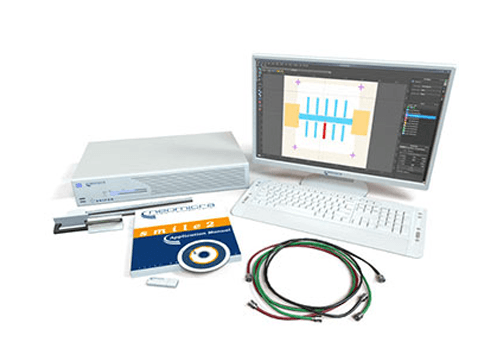

Neomicra Smile 2

neomicra’s smile2 e-beam lithography solution can be attached to any electron microscope or focused ion beam (FIB) microscope.

neomicra smile2 – A Versatile Electron Beam Lithography Solution

neomicra’s smile2 e-beam lithography solution can be attached to any electron microscope or focused ion beam (FIB) microscope. In contrast to traditional electron beam solutions, smile2 is based on state-of-the-art computation technology, combined with a powerful and precise IO hardware. This makes smile2 highly modularized and configurable. Customers can easily build a system which matches their needs.

High Performance & Flexible Pattern Generation

No matter how creative and complex your ideas are, anything can be realized with the help of smile2. Using smile2 allows not only the exposure of many millions of polygons within a few seconds, but also the realization of procedurally computed complex structures, such as fractals, at maximum resolution. smile2 has no dedicated pattern generation (PG) hardware. All points and data required for the beam(s) control are generated with the help of an efficient software module. The main advantage of the system is that the PG does not depend on the structure complexity, so that any complex geometry can be exposed quickly and reliably. The PG can be influenced by the user by determining the method of exposure to improve the final result.

High Resolution Proximity Effect Correction

Thanks to smile2 technology, it is now possible to individually address the dwell time of all potentially 4.3 billion sampling points. Based on this, smile2 offers fully integrated proximity effect correction (PEC) with two different evaluation methods. The first method is the traditional one also used by other applications. The second one is a novel “deconvolution” method which can simultaneously get corrections for both shape and dwell time. Instead of employing geometry fracturing, in order to expose dose-corrected structures, smile2 uses “elementary time partitioning” technology to modify the dwell time locally at each individual raster point. This results in significant improvements, and in an increased reliability – especially for small structure elements.

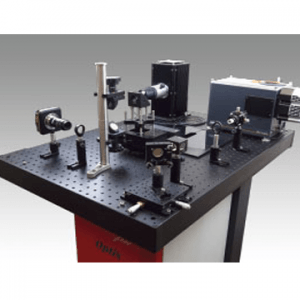

Fast & Precise IO Hardware

Even though the pattern generation is implemented in software, proper IO hardware is required to drive the SEM and beam blanker, and to acquire data from the detectors. smile2’s latest hardware increases the sampling speeds up to 100 Mega samples per second with 16 bit precision and can drive 4 axes (dual-beam) simultaneously. It incorporates novel technology that allows smile2 to set the dwell time for each of the potentially 4.3 billion sampling points individually, without increasing the exposure time. This makes it possible to fabricate high-resolution 3D structures and to improve the proximity effect correction to previously unreachable accuracy.

Flexible and Automatable Workflow

No matter how unique and complex your structures and workflow, everything can be optimized and automated in smile2. The multiple structure exposure allows you to write structures from different documents in one procedure, with their own parameters and enabled layers. It is also possible to control the SEM parameters such as focus distance, aperture and cathode voltage directly in the software. Moreover, every single structure can be aligned fully automatically if desired. smile2 exposes its complete functionality as a set of PYTHON modules. Therefore, all tasks also can be performed through scripts.

Related products

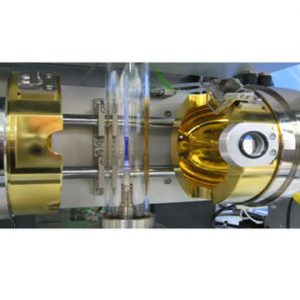

Quantum Design

The high-performance, compact IR Image Furnace from Quantum Design offers unsurpassed performance in a convenient, stand-alone design. Rivaling much larger and more costly IR furnaces, it uses the Floating Zone (FZ) method to promote single crystal growth from a polycrystalline rod.

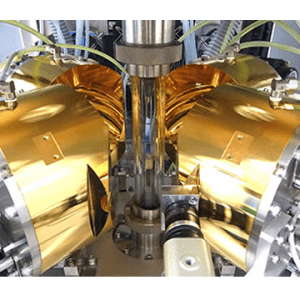

Quantum Design

Quantum Design brings its 30+ years of low temperature instrumentation design to the development and manufacture of an innovative line of compressors and Gifford-McMahon (G-M) closed-cycle cryo-refrigerators. Variable speed energy efficiency, longer uninterrupted run times between servicing, and low vibration operation are all hallmarks of these cryogenic refrigeration products.

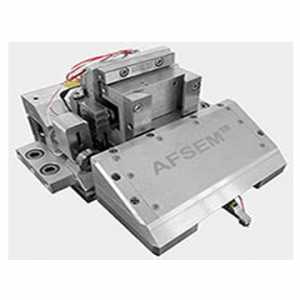

Quantum Design

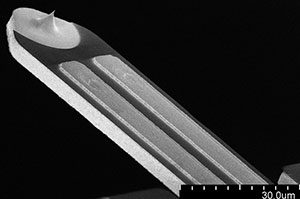

AFSEM™ is an atomic force microscope (AFM) by GETec Microscopy, designed for integration in a SEM or Dualbeam (SEM/FIB) microscope.

Quantum Design introduces its first portable, cryogen-free cryocooler-based material characterization platform – VersaLab. With a temperature range of 50 – 400K, this 3 tesla platform is perfect for accomplishing many types of materials characterization in a limited space.

Quantum Design

Quantum Design brings its 30+ years of low temperature instrumentation design to the development and manufacture of an innovative line of compressors and Gifford-McMahon (G-M) closed-cycle cryo-refrigerators. Variable speed energy efficiency, longer uninterrupted run times between servicing, and low vibration operation are all hallmarks of these cryogenic refrigeration products.

Quantum Design

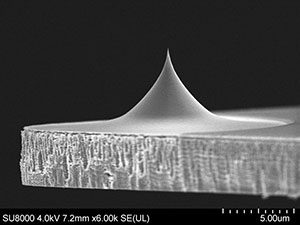

This is considered the standard type of self-sensing cantilever. It exhibits a sharp tip made of silicon with a tip radius of <15 nm. Normally, the cantilever is delivered on our cantilever PCB (CL-PCB) with a small 10 pin connector on its lower side. On request you can order only the Si chip without PCB […]

Quantum Design

Quantum Design's Advanced Technology Liquefiers (ATL) along with its innovative Helium Recovery, Storage & Purification Systems allow you to recover and liquefy the helium gas currently being lost from the normal boil off and helium transfers of your cryogenic instruments.

Quantum Design

Quantum Design’s innovative SHGMS system offers high processing capacity in a compact, modular design with fully cryogen-free operation.