Many applications require that the sample is moved, for example:

- Precise alignment of the sample to the optical path

- Scanning of the surface

- Large range of motion, for example, moving between a reference spot and a measurement area to remove the effects of the optical path

System engineers will assist in the selection of the appropriate window assembly for proper optical access geometry.

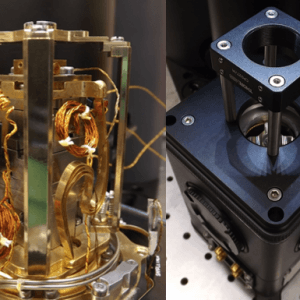

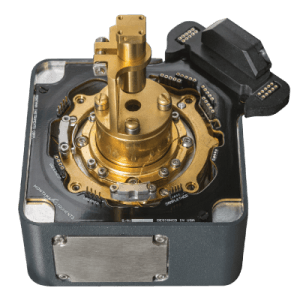

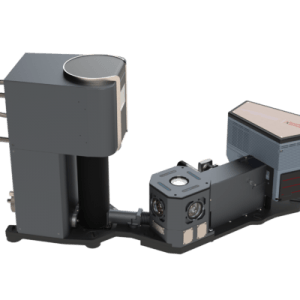

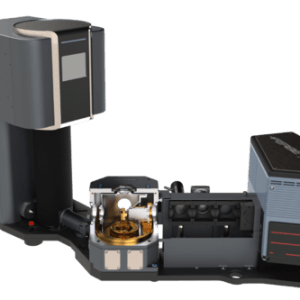

INTERNAL NANOPOSITIONER OPTIONS

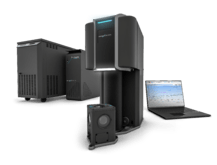

There are several approaches to move your sample with respect to the optics. Consult with Montana Instruments for help choosing the best positioning solution for your setup and application.

Nanopositioner Selection

When deciding which nanopositioners are required for a specific setup, users should:

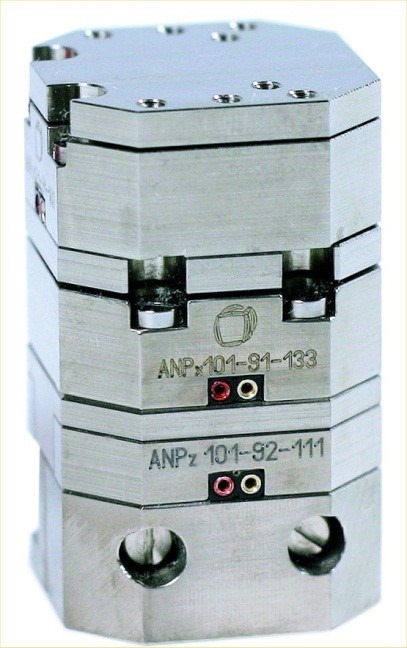

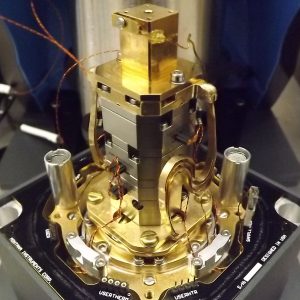

- Decide on the motion direction, magnitude, and precision required. Nanopositioning stages are available in linear (x/y), vertical (z), rotation, or tilt. Stages can typically be stacked — a common XYZ stack configuration has the Z stage on the bottom and X and Y on top.

- Determine the number of stacks required. Dual and triple stack setups are often used in RF and fiber probe setups.

- Decide if you need absolute position feedback (closed-loop).

- Select the proper stage controller. Stages can be driven with coarse stepping via the slip-stick principle or by fine positioning/scanning via DC offset voltage.

- Discuss the stage size, stage stack height, and the position control required with your system engineer.

- Work with your system engineer to confirm interfacing, sample mounting, optical orientation, thermal linking, and other integration details.

Montana Instruments will work with users to select and source the proper stages for your application. Stages purchased with the system will be integrated during manufacturing to ensure components arrive tested and working with your particular setup.

Note: The use of nanopositioning stages may affect sample vibrations and base temperature. The degree of impact depends on the stage used and the rest of the configuration design.

Open vs Closed-Loop Stages

Open-loop stages do not have feedback, so they are usually used for experiments where you want to “find” an area of interest, perform your measurements there, then move on to the next site. Open-loop stages typically offer the most precise resolution. Closed-loop stages allow the user to find features of interest then go back to them later. In this mode, stages have less resolution (approximately 1-2 µm). Systems with closed-loop stages can be easily switched to open-loop operation, but open-loop stages cannot be converted to closed-loop.

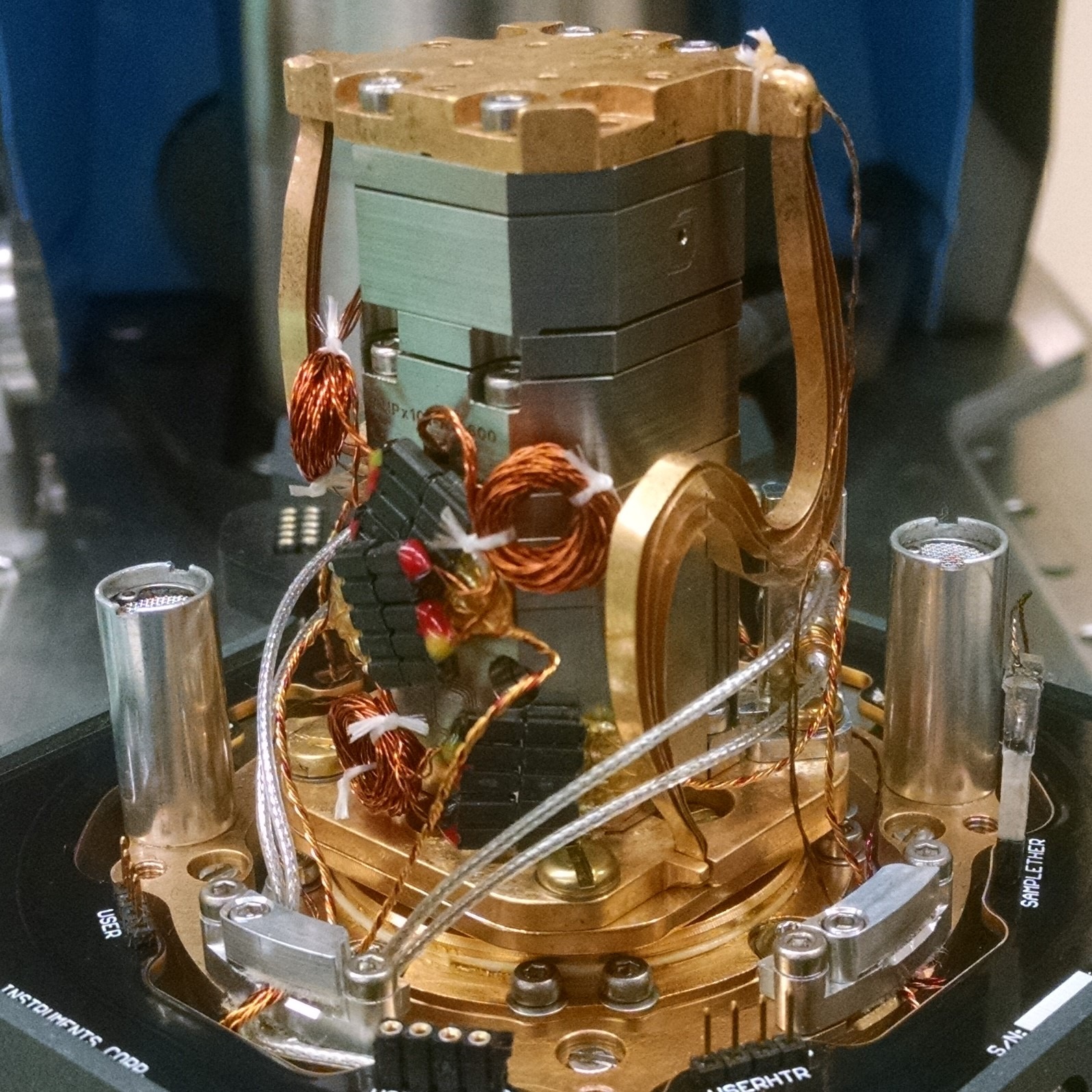

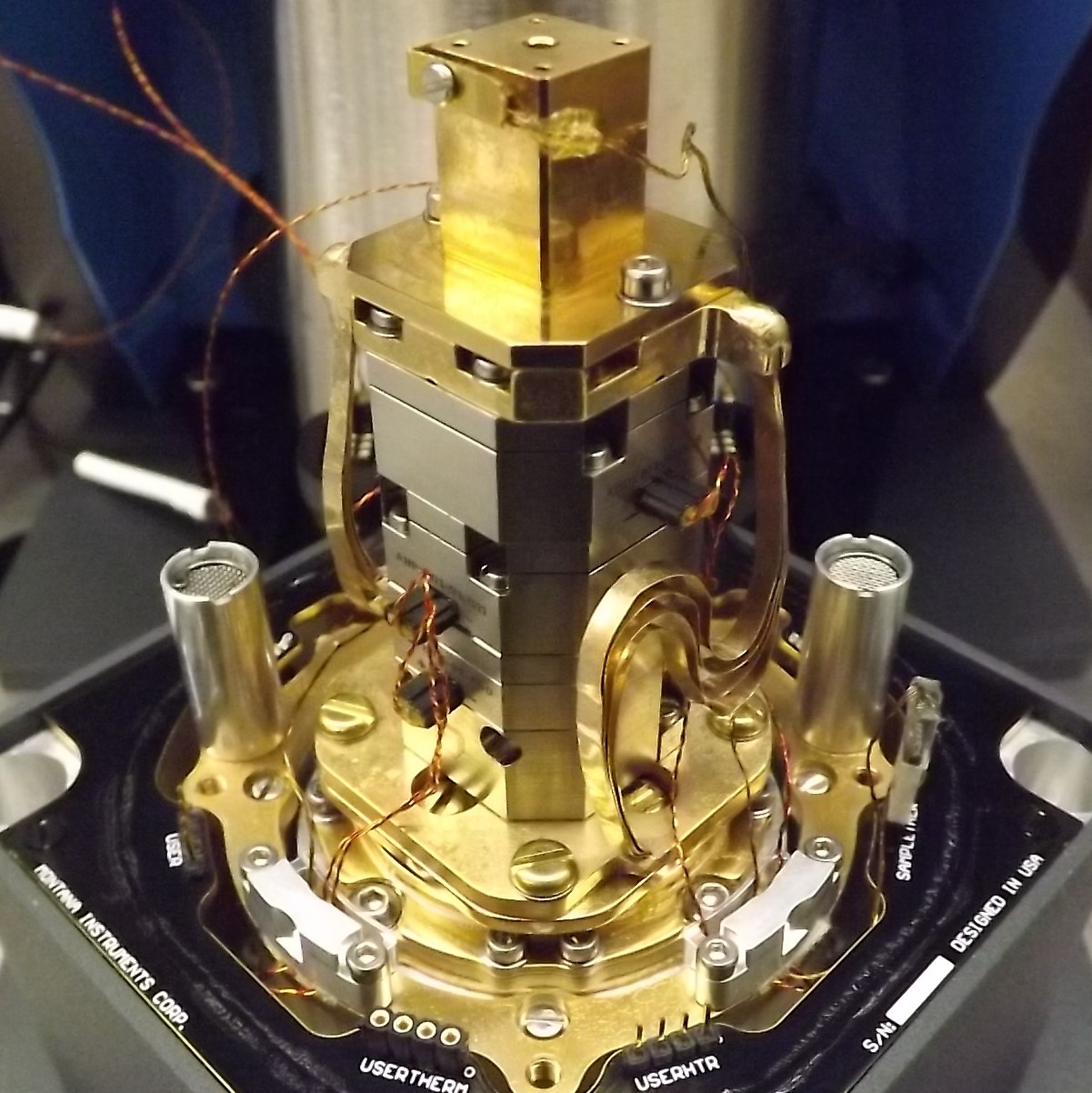

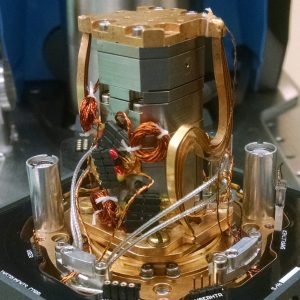

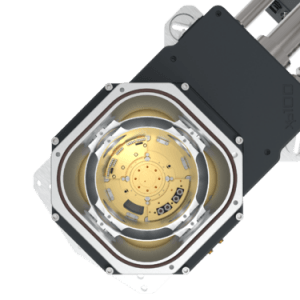

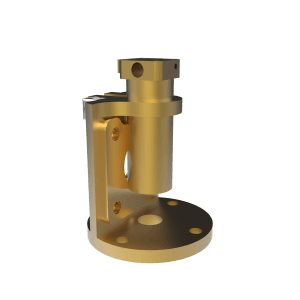

FLEXIBLE THERMAL LINK

Nanopositioning stages are weak thermal connectors, so a flexible thermal link is required to thermally connect the sample mount on the top of the stages to the cold platform. Montana Instruments offers a proprietary thermal link to keep the sample temperature within 0.2K of the platform. These thermal links are custom-designed for the stack height with the flexibility to allow stage movement across the full travel range.

|

|

|

USER-PROVIDED STAGES

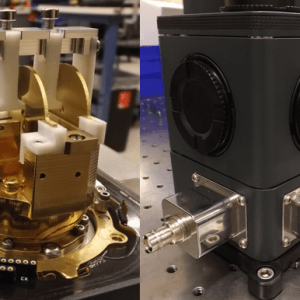

In some cases, the end user may provide nanopositioning stages to be integrated into the system. Users may already have stages or may acquire them via another channel. In these cases, the end user may send the stages for integration into the system at Montana Instruments. We do not recommend users integrate stages themselves, as the subtleties of wire selection, routing, and thermal lagging and the design of proper thermal connections and sample mount schemes are critical to usability and performance. Improper installation of stages can affect system performance.

For a minimal cost, Montana Instruments will install, wire, integrate and test user-supplied stages during manufacturing. This process typically involves selecting and installing a flexible thermal link and sample mount, providing the proper wiring to minimize heat loss, installing and thermally lagging the wiring properly, and testing the entire assembly at low temperatures to ensure optimal performance. We will test for range of motion, stage functional problems, and thermal performance in the system. We do not test for vibrations of the sample on top of the stack unless the end user has requested and paid for this service.

Note: Beyond integration, Montana Instruments does not offer support for user-supplied stages. End users must work with the manufacturer directly to resolve any stage-specific issues.

USER INSTALLATION

Stages are typically shipped integrated inside the system unless the user has alternative configurations or there are concerns about safety during shipping. If stages are packaged separately or if users need to remove and reinstall them, the help article How to Install Nanopositioners in Montana Instruments Systems provides a series of step by step videos showing proper assembly, wiring, and installation techniques. If done carefully, the process should take approximately 30 minutes. Montana Instruments service engineers are available to guide users through this process.